I’ve written on a bit about the Omni Faceting Machine head design in my GemologyOnline post.

One thing that I noted was the Omni Facet Head has the index pin on the bottom of the head. At the time I wrote the article I noted that I didn’t like it because you have to life the head up to see what index you’re on. Since then I’ve realized that there are other drawbacks to having this located on the bottom of the faceting head.

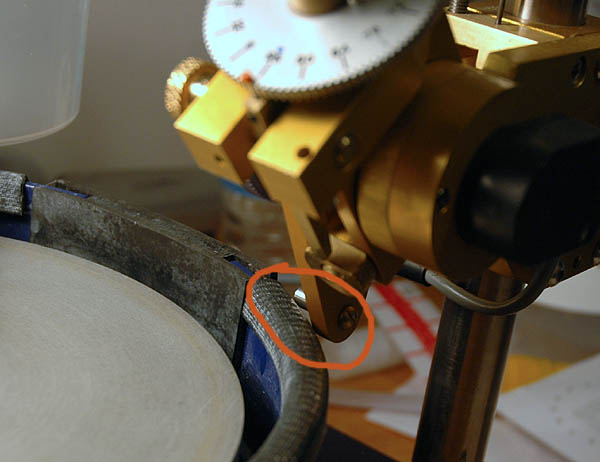

Have a look at this photo. You can see that I have a stone that I wanted to preform on the dop, and the head is set to 59.5 degrees. The lap on the machine is an old Crystalite 600 plated lap, about 1/2″ thick. I’ve lowered the Omni Facet Head so the stone is almost touching the lap.

Now look at the close-up photo. Notice that the metal parts that house the Cheater and Index Pin are bulky and now contact the edge of the Splash Pan. This severely limits the movement of the stone across the lap.

Here are two photos showing a top view. Notice that you only have about 1″ of travel across the lap before the stone either hits the lap screw or the Facet Head hits the edge of the Splash Pan.

What this means is if you are cutting a stone at an angle higher than about 50 degrees, you will have to cut the stone through the girdle cut-out in the Splash Pan. This means you will need to change the orientation of the Swing Arm (and consequently the stone’s orientation to the Platen and lap).

This is bad – in order to maintain the same alignment of the stone to the lap, you should be cutting swinging the stone from the 6 o’clock position to the center of the lap as much as possible. By forcing you to cut in the girdle-grinding position, you have much less travel (due to the limited size of the Splash Pan cut-out) and you are also not cutting on the optimum areas of the lap. It’s also one of the reasons I’ve been frustrated trying to cut rectangular and step-cut stones – moving the Swing Arm position changes the orientation of the stone to your lap.

A final gripe is that if you’re cutting a facet with the Facet Head low and then swing the Quill up to look at the stone, you run into the problem of knocking the Fine Adjustment Arm against the Splash Pan. Irritating and it will change the angle that the Facet Head is set to.

BTW – the stone in the pic is a nice big piece of Afghan Aquamarine 17x9x10 mm, Internally Flawless. I can’t remember how many carats. It’s a beautifully-formed crystal with sharp edges and termination at one end. Pale, as all Afghan Aquamarine tends to be, but very very bright once cut. I’ll post a pic once I’m done.

Allan,

While I agree that the fine adjustment arm/hard stop arm running into the splash bowl is irritating, it can also be downright devastating. If the swing arm strikes the splash bowl when you lift the quill quickly, chances are, this will knock the stone out of your grasp–especially if your hands are oily from polishing with diamond. This is an unfortunate consequence of the design. I have had this exact thing happen when polishing a small spinel trillion. When I lifted the quill to inspect the stone, the arm struck the splash bowl and caused the quill to be forcefully knocked from my grasp and down onto the rotating lap. The stone was ejected from the dop and my Batt lap was gouged badly enough to require resurfacing. Although not expressly a “faulty” machine issue, care needs to be taken to swing the quill out of the bowl before lifting the quill.

After a year layoff I’ve started back cutting. My Omni is five years old and in the four years I used it I didn’t have any alignment problems. Now, I’m seeing a noticeable high left cut – very noticeable on rectangles. I can cheat it into square but that causes havoc with subsequent cuts and polishing. I thought about contacting Jersey Instruments (Charlie, I believe) and arrange to send the head back for a tuneup. Any relevant thoughts or opinions will be appreciated.

Richard

Atlanta, GA

Hi Richard – I can’t say that I’m the most objective person to ask about this as my experience with Charlie has been poor. When I sent my machine back for adjustment it came back in worse alignment than when I sent it, and I was charged $235 plus shipping for the privilege. It’s the reason I started taking apart my machine and documenting the process – initially so I would remember what I did, but also to assist some other owners who’d been in contact with me about similar problems.

I’d call Charlie and talk to him about it. If the Omni is still under warranty, I’d send it back and see what happens. If not, I’d suggest taking a look as the alignment instruction pages “Alignment Steps” at the top of the page to see if any of these may provide some insight. I’m not sure how comfortable you are with taking machinery apart, but if you’re not comfortable find a friend who is, or send it to Charlie as then you’ll have some recourse if things don’t work the first time.

http://www.omnifaceter.net/alignment-steps/

Good luck, and le us know how you make out.

-Allan