Here’s a quick pictoral guide to how I created my $5 custom splash pan for my Omni-E faceting machine. This is a more detailed set of pictures and instructions than in my blog post $5 + 2 Hours = New Splash Bowl.

Please remember that I’ve modified my Platen so it is now 4″ in diameter, not 6″. This is key as it will determine what you will use to create the new Splash Pan.

You will need to remove your existing Splash Pan – follow the instructions in my Removing the Platen and Spindle and Removing the Splash Pan posts.

Get the Parts

First, go find yourself two plastic containers – I went to the local Dollar Store and found a nice big plastic bowl that was about 10″ in diameter on the inside. The other container was a pasta container (similar to a 1 quart yogurt container) that was about 5″ in diameter. I also picked up one of those thin flexible poly vegetable cutting mats.

And then I went to the local Medical Supply shop to buy a foot of the thickest rubber exercise bands (“Theraband”) material I could find. This rubber and the cutting mat will become the splash pan cutout thingie. You will also need some Silicon Sealer plus some sort of drain tube.

I used the following:

- 10″ Diameter Plastic Bowl (from Dollar Store)

- 5-1/2″ Diameter Pasta Storage Container (from Dollar Store)

- Poly Cutting Mat (from Dollar Store)

- 1 foot of Theraband rubber (from Medical Supply shop)

- 6″ of 5/8″ Diameter Surgical Tubing (from Medical Supply shop)

- Black Silicon Sealer

- Body of a thick plastic pen (to be explained later)

Plastic Bowl from the Dollar Store

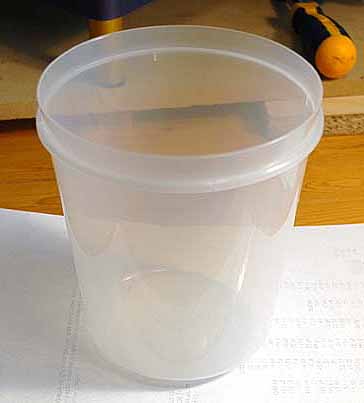

Pasta Container from the Dollar Store

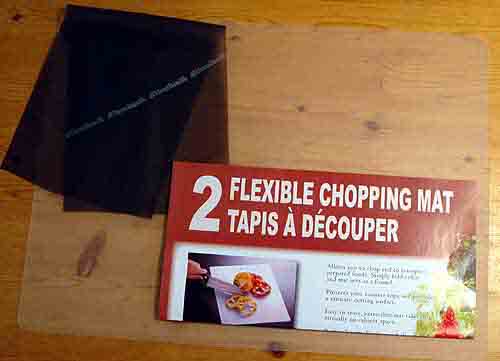

Theraband Elastic and Cutting Mats

Make the Collar

Cut the pasta container so that it now fits easily over your Platen with at least 1/4″ to spare around it. Put this over top of your Platen so you can now see how tall to cut it. Mark it with a pen and then cut it to create a nice collar that ends about 1/8″ or so below the bottom of the Platen.

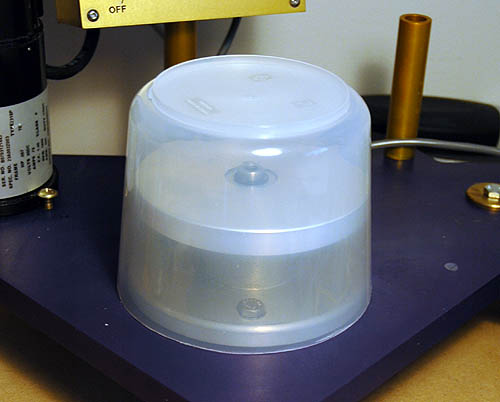

Pasta Container Cut to fit Omni Platen

Pasta Container Cut Just Below Platen

Fitting the Collar to the Splash Bowl

Now that you’ve got the collar created, it’s time to cut the bowl so it fits.

I used a drafting compass with the pencil lead replaced with a second pin to scribe a circle slightly less than the outside diameter of the collar in the bottom of the bowl. I then carefully cut the bottom bit out of the bowl.

Disembodied Hand Scribing the Bowl

Bowl Bottom Cut Out

Using a wood file I carefully enlarged the cutout so that the collar could slide half-way through the opening. I left a little more than 1/2″ of the collar sticking out of the bottom of the bowl.

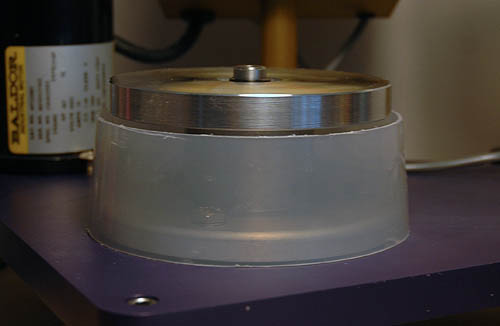

Bowl with Core Inserted

I now cut the bowl down to a reasonable height – total height of Collar plus Bowl is about 4″ – so I cut the bowl down to be 3-1/2″ from bottom to the new lip. When taking this photo I nearly cut myself!

Cutting the Bowl to Proper Height

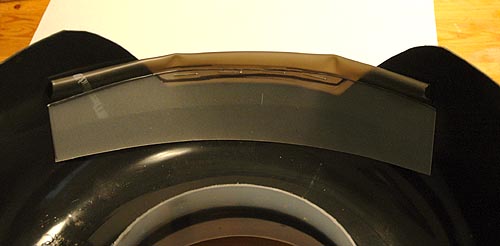

Collar and Bowl Together

Now to test the whole assembly before silicon sealing the whole thing together:

Make the Drain and Seal Together

I forgot to do this step until after I sealed everything together. Probably the wrong time to do this!

Figure out where you want your drain tube to come out and at what angle. For me, I needed to have it come out the back of the new Splash Pan at an angle so it wouldn’t interfer with the way the assembly sits on my Omni faceting machine.

I used the barrel of a very ugly and fat plastic pen to create the drain. Carefully cut a hole near the edge of the bowl so that the tube you use will stick out at the correct angle – it will be oval or marquise-shaped depending on the angle you want it to come out. Carefully file the hole so the tube fits reasonably well.

Now carefully use the silicon to glue the collar and bowl together. Set aside to dry a bit – at least an hour so the sealer skins over and you won’t knock the thing apart handling it.

Now get out the Silicon Sealer and goop silicon around the drain tube and hole to hold it in place. Don’t forget to seal the inside of the bowl too – but be careful to leave it flush with the inside of the bowl. Let the whole thing dry overnight. (BTW – I didn’t let it dry before continuing. I ended up having to re-seal everything later)

Splash Pan Drain Tube

Splash Pan Drain Inside View

Make the Girdle Cutout and Splash Guard

Once the new Splash Pan assembly is dry, set it over the Omni Platen. Put a lap on your Platen and then using a marker, draw a nice girdle cut-out slot on your new Splash Pan. Be sure to make it 3-1/2″ wide at the bottom so that you have enough space to swing the dop but not so large that water will spray everywhere. I made mine 4″ wide.

Carefully cut the opening. I used smooth curves so that the plastic wouldn’t crack or break at the cut corners.

Make the Girdle Cutting Slot in Splash Pan

Now take the poly cutting mat and stick it into the Splash Pan somewhere other than the Girdling slot. Hold it against the inside of the bowl and use a pen to mark where the top of the bowl is. Remove the mat. You now have a nice arc that will match the edge of the Splash Pan.

Girdle Splash Guard Step 1

Girdle Splash Guard Step 2

Mark out the size of the girdle splash guard on the plastic mat. Cut two identical pieces from the poly mat, then put one of them in the Girdling Slot you cut so that the top of the piece is just above the girdle cut-out. Mark this line.

Girdle Splash Guard Cutout 3

The rubber Theraband is going to be a soft bumper on the top of the Splash Guard. Cut a strip of the Theraband about 1-1/2″ wide the length of the plastic strips. The Theraband is to be folded and sandwiched between the two poly sheets.

I can’t think of a way to describe what to do next, so I’m just going to show you the pictures of what you’re supposed to do. I used staples to hold the whole mess together and then put some silicon over the staples so they wouldn’t rust. This has proved quite effective and has not fallen apart or loosened up yet.

Girdle Splash Guard Step 4

Girdle Splash Guard Step 5

Girdle Splash Guard Step 6

In this last picture I’ve trimmed the Splash Guard and glued the loose flap of Theraband to the plastic with silicon sealer.

Girdle Splash Guard Step 7

Water Drip Cutout

The final step is to create the cutout so the water drip spout can move and sit properly. Put the new Splash Pan on your Omni faceting machine and mark where the drip spout needs to go. Cut this out.

Here are two pictures of the completed splash pan without the Girdle Splash Guard and with it in place.

Water Drip Cutout

Water Drip Cutout with Girdle Splash Guard in place

Oh, and don’t forget to put the tubing on the end of the water drain tube before you use this!

My new Splash Pan can hold bowl more than the contents of one full water drip container without overflowing! Mind you, at high speeds the wind from the laps will cause the water to rotate and then it will overflow, so I don’t suggest using this Splash Pan without the drain.

Enjoy! Let me know how your splash pans turn out!