So after all this time, why would I suddenly decide to take my Omni Faceting Machine’s most delicate components apart? If you’ve been following my Blog entries you’ll remember the Another Frustration – Quill Runout post.

To be to the point – I was alerted by others to yet another manufacturing defect and quality control problem with the Omni Faceting Machine. After experiencing the same sorts of frustrations cutting stones and finding the machine out of alignment, other Omni owners noticed that the Quill wobbles about the long axis. In other words, it doesn’t spin true and has a large runout.

Others have told me they have measured 0.0055″ to 0.0075″ runout on their quills. I have measured 0.0035″ runout on mine, and now I understand why I have such problems with cutting by sound or by the angle-indicator. Depending on what index position you’re cutting, the Quill will be closer or further from the lap than another index position!

To put it in perspective, the Polymetric Scintillator states that their Dop Arm (Quill) is adjustable to 0.0002″ Total Indicated Runout. This is between 17.5 to 37.5 times more accurate than the Omni measurements I’ve received!

In my opinion, any Quill runout of more than 0.001″ is unacceptable.

I decided to take my Faceting Head apart to see if there was any way to adjust the Quill runout. There is not.

First Step

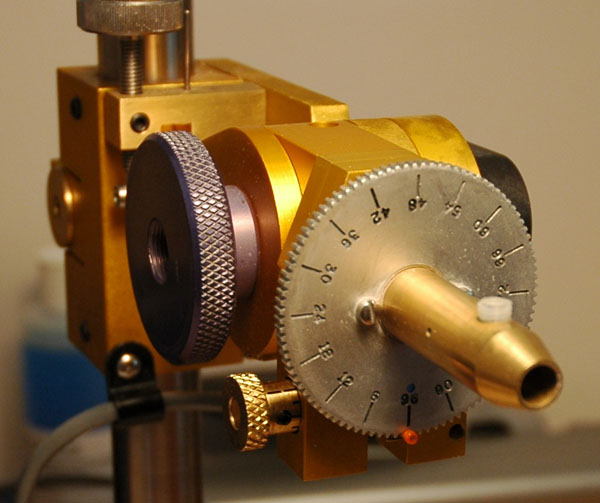

To get at the screws mounting your Quill to the Omni Faceting Head, you will need to remove the Index Wheel.

Lock the Index Pin up so the Quill is in free-wheel mode. Using a slot screwdriver, carefully remove the two screws holding the Index Wheel in place. Gently ull the Index Wheel and slide it off the Quill. It may need a bit of WD-40 to loosen any corrosion and rock dust so it can slide off the Quill. Be careful not to pull the little bead off the end of your Index Pin.

Omni Faceting Head showing Index Wheel screws

There is a brass ring which the Index Wheel screws into. You can remove this from the Quill by loosening the Allen screw holding it to the Quill and slide it off also.

Your Faceting Head will now look a bit naked, like this:

Omni Faceting Machine Quill with Index Wheel Removed

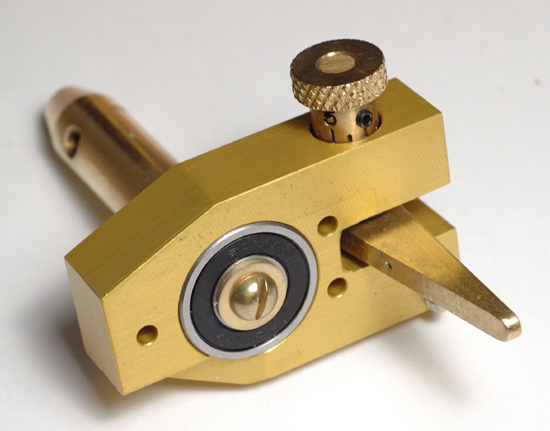

Removing the Quill Assembly

Using the appropriate size of Allen key, undo the 3 screws holding the Quill and Yoke to the Faceting Head. Be careful as the last screw is removed – the Index Pin is spring-loaded and will push the Yoke. You don’t want to drop this part!

Carefully remove the Index Pin Spring and put it somewhere safe with the Allen screws.

Your Quill and Yoke assembly is now free of the Faceting Head.

Omni Faceting Machine Quill and Yoke Assembly

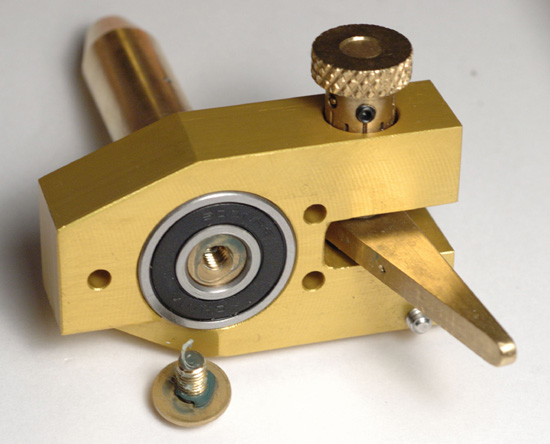

The Quill

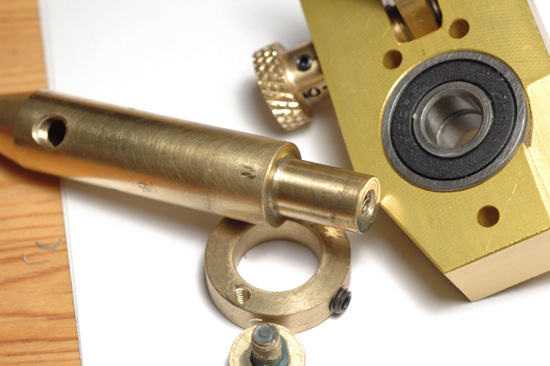

As you can see, the Quill is held into the Yoke by a bearing and a screw in the back of the Quill. I removed the screw. You can see the screw has some sort of Locktite on it to prevent it from loosening on its own.

Omni Faceting Machine Quill and Yoke Assembly with Screw Removed

About here I had the shock of my life – as I picked up the Quill and Yoke assembly, the Quill fell out of the bearings under its own weight! I had fully expected the Quill to be press-fit into the bearings to ensure that the Quill didn’t wobble in the inner race. I was wrong.

In this picture you can see the base of the Quill where it fits into the bearings. Notice that there are no scratches or other marks from when it fell out of the bearings – it sits in there loosely. How one can expect to have a precise alignment when the shaft does not fit tightly to the bearing is beyond me.

Close-up View of the Quill base

The Yoke

I’ll resist saying “the Yoke’s on you”… or maybe not 😎

The Yoke has two 6000RS bearings which the Quill slides into. What you can’t see from the photo is that the two 6000RS bearings are not just press-fit into the Yoke body but they’re resting against a fin of metal machined into the Yoke between the two bearings.

This means you’re not going to be able to replace the Yoke bearings very easily, if at all. I had to get my machinist make a special tool to pull them out so I could replace them with some higher-tolerance ABEC-3 rated bearings. I was told that this was a very difficult process.

Omni Yoke showing the pair of 6000RS bearings

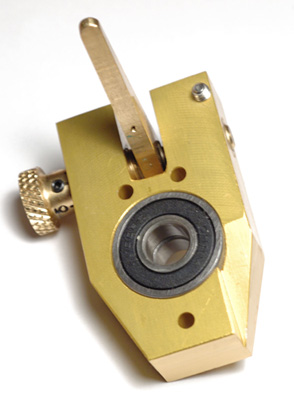

Here’s a view of all the parts of the Quill and Yoke assembly together.

Omni Quill and Yoke Parts

My Custom Quill Design

After some discussion with the other Omni owners and the machinist, I have designed a replacement quill to be made out of Stainless Steel.

Brass does not have very good properties for retaining shape – so if you accidently bang it or somehow flex the thing, it’s not going to spring back but stay in the new shape. Stainless Steel will bounce back, plus it’s much harder and stronger.

An excellent suggestion from one of the other owners was to make the Quill with a collet to hold the dops rather than a set-screw. This does two things – it makes it easier to put the dops in and out (no mis-placing the bloody Allen key) and it helps keep the dops centered even when they are a bit worn.

The Quill is still being fabricated but as soon as I get it I’ll be posting photos. I have asked to have a few extra made up (the cost is mainly in getting the machines set up, not in producing the pieces) so if you want to replace your brass quill with a stainless steel collet quill I can sell you one.

In the mean time I’m eagerly waiting.

Hi Allan!I want to replace the bearings in Omni facet head.Where did you buy the bearings 6000RS with are ABEC-3 tolerances?I am out of USA.

Regards

Michael

Hi Michael – I purchased them online from an ebay seller… a fellow who went by bobhill5. I just checked and he’s no longer selling on ebay.

Do a search for “6000RS ABEC3” and you should find someone selling them. I think I paid around $2.50 each. They were in a gold box with “RB Tech” as the brand. Unfortunately I have moved, otherwise I’d just send you a couple as I have a few sitting in a box – that’s now about 6000 miles away. Oh well 🙂

Good luck!

-Allan

Hi Allan!Do you remember the sizes of bearings in facet head:shaft and outside diameter,width?Inch or metric?

Regards

Michael

Hi Michael – sorry for the very slow response… somehow I missed this one. Offhand I don’t recall the dimensions of these bearings, but if you do a search for “6000RS” you will find some pages with the specifications.

Good luck!

-Allan