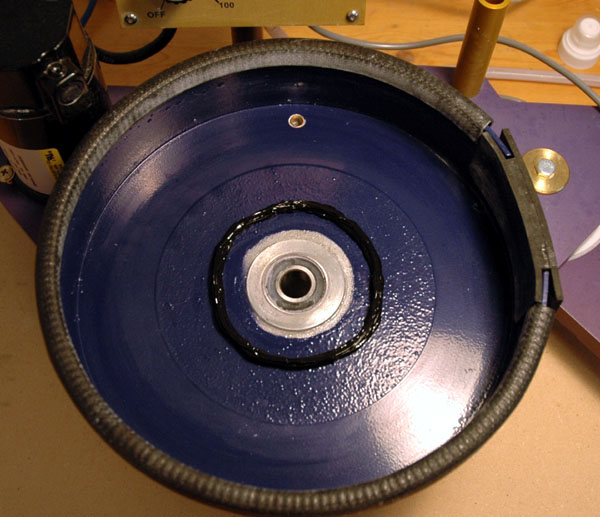

Here is a simple modification I did to my Splash Pan to help protect the Spindle Bearings and other components from water and corrosion.

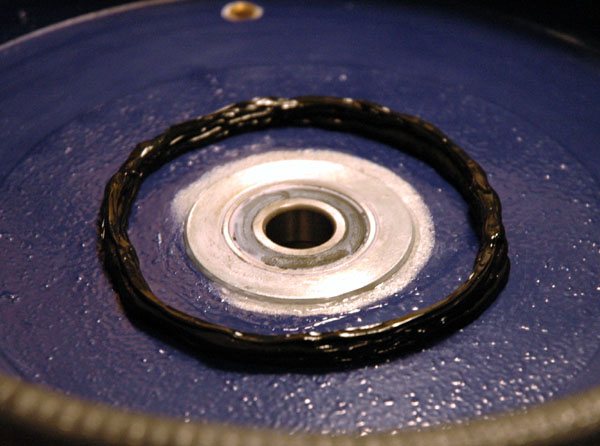

After disassembling the Platen and Spindle and Splash Pan I washed out all the rock dust and grease. I then put a bead of silicon rubber around the center of the Splash Pan (the stuff I have is black but any will do). This bead is about 1/4″ high, and should prevent any water from inadvertently getting down into the Spindle Bearings or between the Splash Pan and Spindle Housing.

Wait for the rubber to dry before replacing your Platen and Spindle.

Be careful that your silicon dam is not too high – if it is, it will rub against the underside of your Platen when you re-install it.

You can also see that I’ve smeared silicon grease into the gap between the Spindle Housing and Splash Pan. This will prevent any water that happens to get splashed over the rubber dam from corroding the Splash Pan and Spindle Housing any more.

This will guard against reasonable amounts of water in the Splash Pan – up to 1/4″ deep. However it’s still not adequate in my regard and I will be making my own Splash Pan (wider in diameter) out of some plastic later.

May I suggest enlarging the drain hole. I can’t remember what size I changed to but it’s about double the size of the original drain. This is one reason the water backs up. I also have my tubing running straight down through a small hole in the table top. hope this helps.